Explore how advanced methods in product development, focused on innovative strategies and processes that enhance efficiency and market responsiveness. It emphasizes the importance of cross-functional collaboration and iterative testing in achieving successful outcomes. By integrating modern technologies, businesses can improve product quality and reduce time-to-market effectively.

Table of Contents

It wouldn’t take an expert to know that the Samsung Galaxy Note 7 launch was a disaster. The flames from the battery were a pretty big sign. By the time it set fire on a plane its fate was sealed (never mind the time it burnt down a car) – the phones were recalled, and the company lost around $17 billion in revenue.

Of course, most product launches don’t end up with the product unintentionally setting fire. At the same time, only around 3% of product launches are considered to be successful – it seems like a lot of products don’t necessarily do anything wrong (at least not on the scale of giving you acute bronchitis), but the vast majority aren’t getting it right either.

What can be done to improve the chances of product launch success? There is something that those 3% of products have gone through to vastly improve their chances of success – they’ve been tested. Not just to pass safety standards (where that applies), but to see if consumers actually like the product.

It’s never been easier to test products – digital mockups can be quickly created (sites like UpWork and Freelancer can help with this), and the latest generation of 3D printers allow physical prototypes to be inexpensively and quickly made (for example with Quickparts, or Hubs). On top of all of this, the rise of VR has made it possible to prototype products and experiences in immersive environments, in a cost-efficient manner.

This stage of prototyping allows you to test how consumers respond to products early on in the process – letting you know if getting the idea of the ground is going to be worthwhile (of course, later on in the process you should probably also check if your product is going to suddenly set on fire too).

Below, we will go through the process of product development, and set out how it can be done to get the most informative results possible.

Product testing

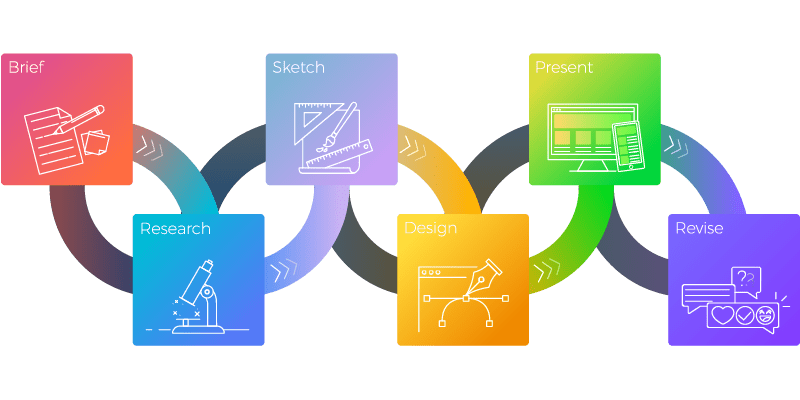

Product development is an iterative process. Ideas for new products rarely arrive fully formed. Products, whether ideated using brainstorming techniques like the SCAMPER process, natural inspiration, or just a stroke of genius, all require further planning.

The first hurdle is research – what you have in mind might already have been in the mind of others – does the product already exist? Is there space in the market? Is there a market for it at all? Finding out the answers to these questions is the first step in understanding if the planned product is economically viable.

Following this, the details of the actual product can be figured out. What will it actually look like? How will it work? What goes where? This is a good time to settle on a few options, and then test these as prototypes. These tests might be the first carried out with the product mockup, but they also shouldn’t be the last.

Prototype testing

The traditional approach of product testing at the mockup stage has simply been to sit down with potential consumers (or at least with people who aren’t directly involved in the product development), and to ask for their thoughts as they handle and manipulate a physical prototype, click through a digital experience, or maybe even taste a food item.

There are two central changes that have occurred to this traditional approach: the first is that products can now more easily be digitally prototyped (for example, with outputs from CAD software) if they weren’t already digital, and the second is the current awareness of how unreliable such testing setups can be. We’ve covered the many biases that are present whenever testing through direct questioning in previous blog posts (e.g. participant bias, selection bias, and researcher bias) but it largely boils down to a single point – people are rarely reliable when describing their thoughts or emotions.

This might not seem like a big problem (after all, it doesn’t mean anything’s going to set on fire) but failing to factor this in can leave you with a product that has been inaccurately tested, and potentially put it in the same league as Crystal Pepsi, the Amazon Fire Phone, New Coke, Microsoft Zune, Facebook Home, Colgate frozen dinners (yes really), and the infamous Microsoft Clippy (and let’s not even talk about Cheeto’s lip balm).

Understanding the product

So how can we test products accurately? First you’ll want to define what you actually want to know about the product, for example – do people like the look of it? Will they see it in a store environment? Are they frustrated when they operate it? How do they emotionally react to it?

With these questions in mind, you’ll be able to set up experiments that aim to give you the answers you need, in any step of the product development process. Biosensors are capable of providing quantitative answers to these questions, allowing you to test what you need to know about products, at any step of the product development cycle. The biosensors most commonly used in product development are:

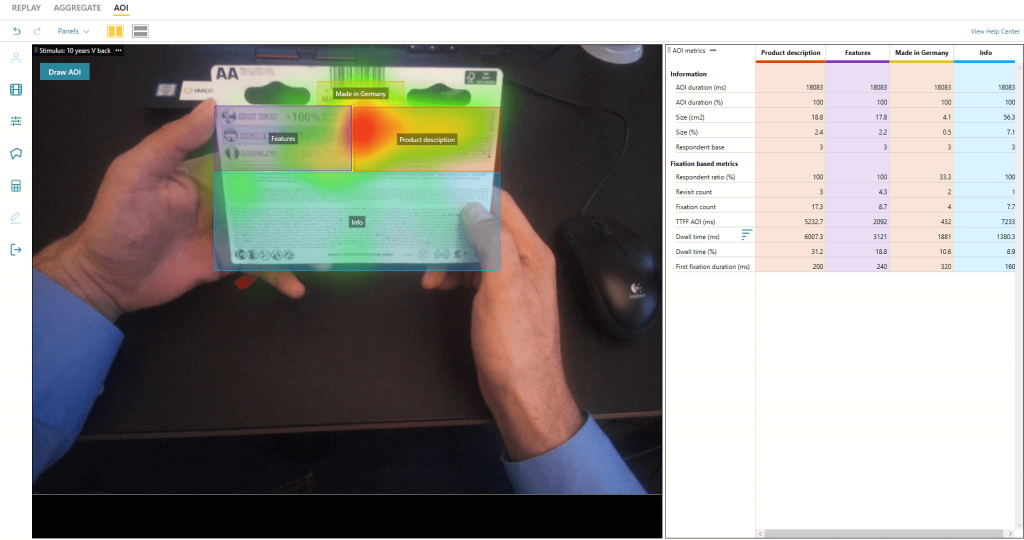

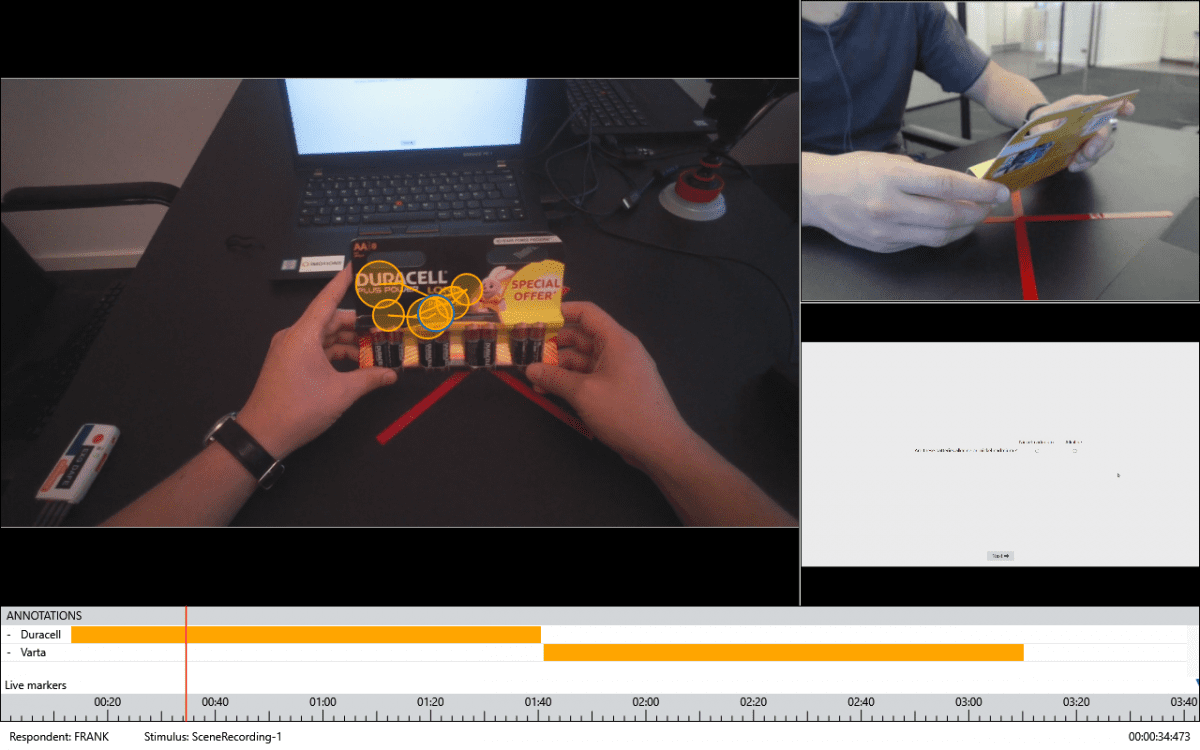

- Eye tracking. This tool can provide you with information about where visual attention is directed when viewing the product – from determining if the right buttons are seen on a physical product, to finding out if consumers would notice it in a shop.

- Facial expression analysis. By recording through a webcam, facial expression analysis can provide you with information about if potential customers exhibit frustration, joy, or surprise with the product (as well as many other metrics, from single facial expression action units, to displays of emotion). This method detects the outward signs of emotion that a user may exhibit.

- EEG. While being a device that requires some training to operate, EEG can be used to provide metrics about a user’s feelings of approach or avoidance. This metric, known as frontal asymmetry, is often used as a proxy of attraction (or conversely, repulsion) towards a stimulus. Other metrics are also available.

By combining this data collection with explicit answers and thoughts from users, it’s possible to synthesize findings to create a deeper understanding of responses. By knowing what is looked at, for example, when a participant says there is something they do or don’t like, their thoughts become more defined in relation to the product. It can help push an understanding along, by providing the data that is often missing from verbal reports.

Check out our guest blog: How food packaging can help children pick healthier products

This data, whether benchmarked, or compared across groups, provides an understanding of how a user actively responds to a product. By using concrete, quantifiable measures, a common language can be developed that facilitates the communication between those who test users, and those who design and build the product. It’s possible to understand specifically what is or isn’t liked about the product, or specifically what is or isn’t seen – moving the discussion from potential ambiguities to defined constructs.

Data-driven product development

The use of biosensors also allows product development to move on the fly. This is particularly helpful in the early stages of product design, where products can be tested digitally (on screen, or even in VR). This allows products to be produced in a relatively cost-effective manner, and for the rapid, iterative testing process to provide answers that can help set the product direction in the right way early on. This saves both money and time – and could certainly steer product designers away from making another Colgate™ beef lasagna.

By collecting data regarding user preferences, and then relating that to how it performs downstream in the market, it can also be possible to build a database that has predictive power of commercial success. This data-driven approach provides a foundation of knowledge from which to base future product designs from. It might not be a crystal ball, but it could be the next best thing.

Conclusion

The commercial landscape for products has never been more competitive, yet prototyping and product testing has never been more accessible. This means that any forward-thinking company is engaging in thorough product testing – raising the bar for product success ever higher.

The use of biosensors employed at any stage of the product development cycle can ensure that the right track is found and kept to. Whether the product is physical, digital, sensory, or experiential, the collection of human-centric data allows for a deep understanding of how humans respond. By getting it right the first time, everyone benefits. And nothing sets on fire.

I hope you’ve enjoyed reading about advanced methods in product development. If you’d like to get a primer on the approach and methodologies introduced in this post, download our free guide below:

Free 52-page Human Behavior Guide

For Beginners and Intermediates

- Get accessible and comprehensive walkthrough

- Valuable human behavior research insight

- Learn how to take your research to the next level